1. The role of agitators

Fermentation technology is widely used in biopharmaceuticals, feed, alcohol, yeast production, enzyme production, protein derivatives, hydrocarbons, beverages, activated sludge treatment and other processes. The fermentation process can be divided into aerobic fermentation and anaerobic fermentation. For anaerobic fermentation processes such as wine and activated sludge treatment, the stirring intensity requirement is very low; while for aerobic fermentation processes, the influence of stirring conditions is very sensitive. The stirring effect in the fermentation process involves gas dispersion, solid-liquid suspension, heat transfer and mixing. The container used in the fermentation process is called a fermenter. The total volume of the fermenter used in actual industrial applications is usually between 50 and 400 m³, and its aspect ratio is generally (2 to 5): 1. The design of the fermenter generally first considers the influence of the empty tank gas velocity. The empty tank gas velocity is converted according to the oxygen consumption of the microorganism, generally between 0.005 and 0.05 m/s, and the maximum does not exceed 0.1 to 0.12 m/s. Considering the requirements of gas distribution, a larger height-to-diameter ratio is conducive to gas dispersion; secondly, the requirements of heat transfer must be considered. The heat generated during the fermentation process is generally discharged by multiple groups of vertical cooling pipes in the tank, and the vertical pipes also act as part of the baffle. The use of a larger height-to-diameter ratio is conducive to increasing the heat exchange area. However, when considering the mixing requirements, a larger height-to-diameter ratio is not conducive to mixing the material up and down, so multi-layer impellers are often used in actual application processes to meet the requirements. The fermenter is one of the most important equipment in microbial engineering. An excellent culture device should be designed with a strict structure, good liquid mixing performance, high mass transfer and heat transfer rates, and reliable detection and control instruments to achieve maximum production efficiency. The most critical design is the selection of the agitator.

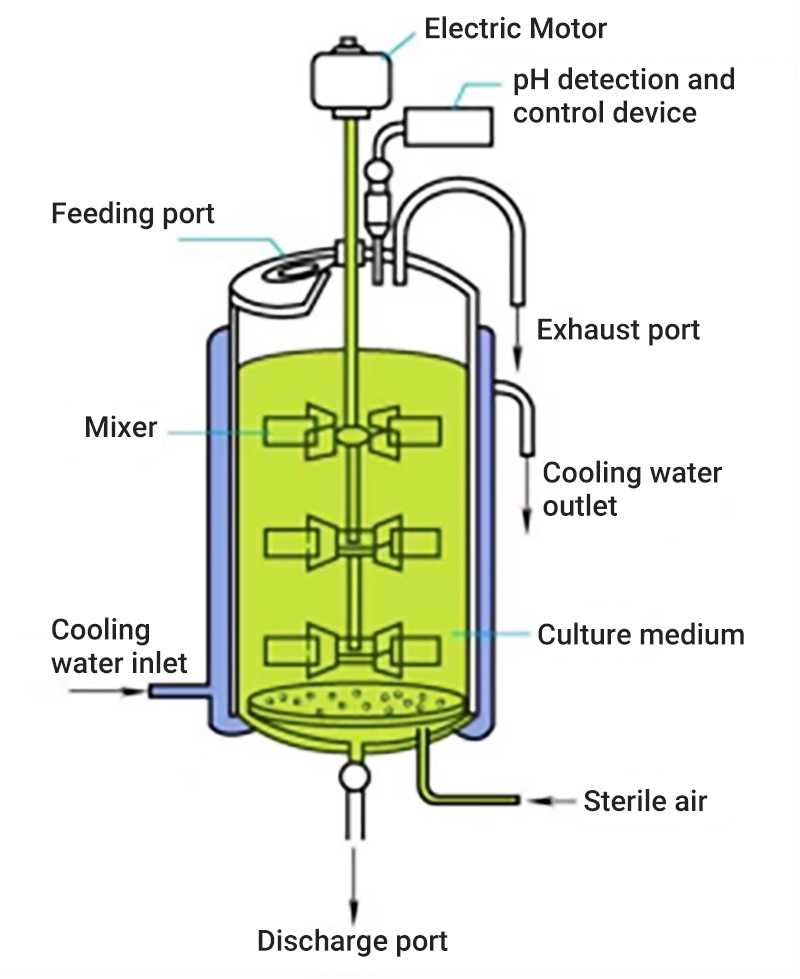

Figure 1 Schematic diagram of fermentation tank structure

The main components of the mechanical stirring ventilated fermentation tank include the tank body, agitator, baffle, cooling device, air distribution device, etc.

2. Classification of agitator types

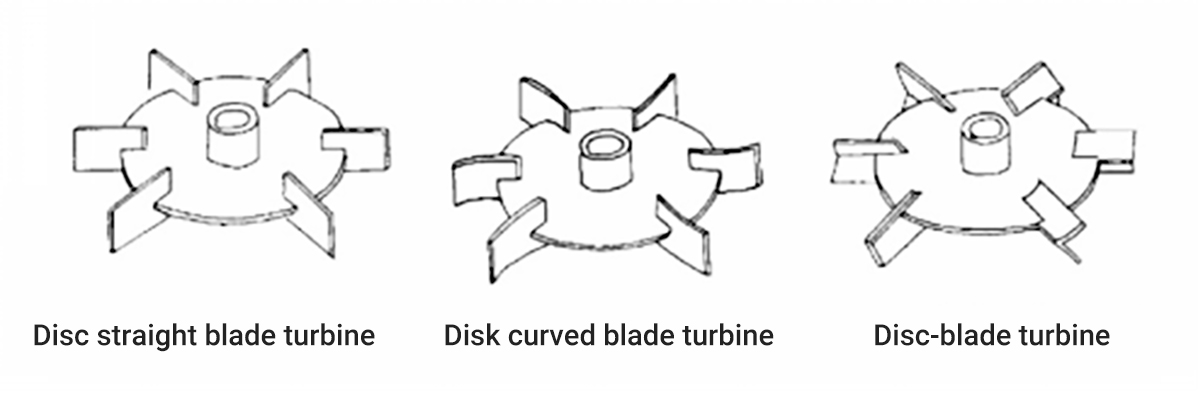

Figure 2 Disc turbine impeller

The agitator is very important for the fermentation state. The main functions of the agitator are: breaking air bubbles, increasing dissolved oxygen, and accelerating the mixing of materials to achieve material transfer and heat transfer.

The agitator includes a stirring shaft and a stirring paddle. A disc is installed in the center of the stirring shaft, and a stirring paddle is installed on the disc. The agitator mainly includes radial type (paddle type) and axial type (disc turbine). The liquid flow pattern formed by stirring is divided into three types: radial flow, axial flow and tangential flow.

3. The difference between several agitators

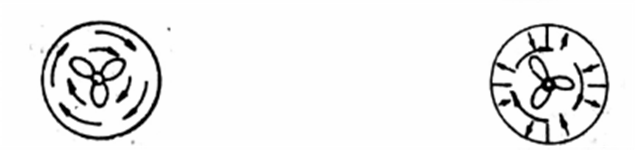

Figure 3 Comparison of flow patterns with and without baffles

Radial flow: The blades exert radial centrifugal force on the liquid. The direction of the fluid is perpendicular to the stirring shaft. It flows radially and is divided into two streams when it hits the wall of the container. It flows upward and downward respectively, and then returns to the blade tip without passing through the blade, forming two upper and lower circulation flows.

Axial flow: The flow direction of the fluid is parallel to the stirring shaft. The fluid is pushed by the blades, causing the fluid to flow downward. When it encounters the bottom of the container, it turns up again, forming an upper and lower circulation flow.

Tangential flow: In a container without baffles, the fluid rotates around the axis. When the flow rate is high, a vortex will form on the surface of the liquid. The flow rate of the fluid from the circumference around the blade to the blade area is very small, and the mixing effect is very poor. Adding baffles can change the flow direction of the liquid, so that the fermentation liquid changes from radial flow to axial flow, promotes violent tumbling of the liquid, and increases dissolved oxygen; prevents the generation of vortices during stirring, and prevents the agitator from failing to stir.

4. Application of agitators in fermentation tanks

Disc turbine agitators are commonly used in fermentation tanks, which belong to radial flow agitators. The disc turbine impeller divides the liquid into two systems, one above and one below, forming oxygen-rich and one below near and far from the impellers, which is not conducive to the mixing of the substrate and the transfer of oxygen. Therefore, axial flow impellers are widely used. Axial flow impellers can make up for the shortcomings of disc turbine impellers and improve the dissolved oxygen effect. However, the use of axial flow impellers alone will also have the disadvantages of more serious liquid tumbling, low fermentation liquid volume, and easy liquid flooding.

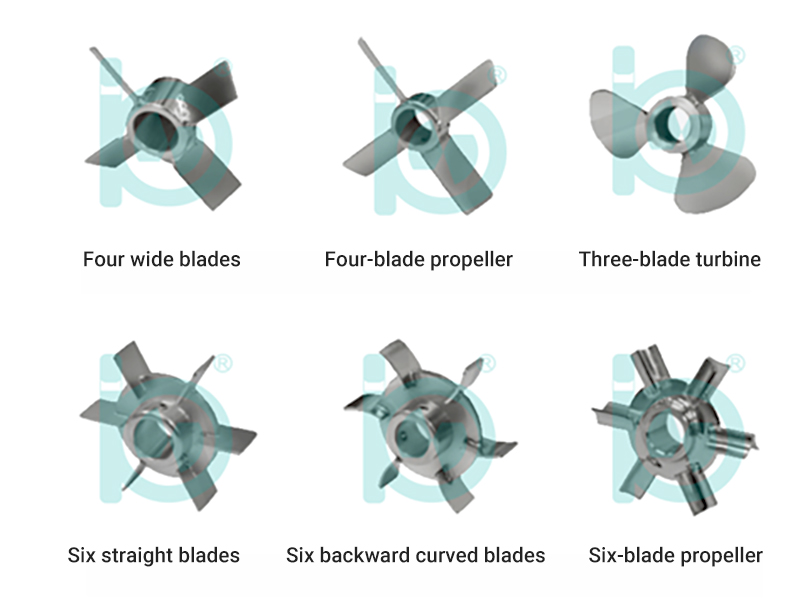

Therefore, two types of impellers are generally used in combination: the lower layer uses disc turbine impellers, which can interrupt the rising airflow and play a role in breaking bubbles. The upper two layers use axial flow impellers, which can increase the oxygen transfer coefficient of the equipment. The bottom layer uses turbine flat blades, the middle layer uses turbine arrow blades, and the upper layer uses four-pitch blades, which can reduce power while increasing dissolved oxygen. However, the combination of different impellers needs to be determined through experiments.

Figure 4 Some propeller blade types