WHAT WE DO

-

Micro Bioreactor

-

Glass Bioreactor Fermenter

-

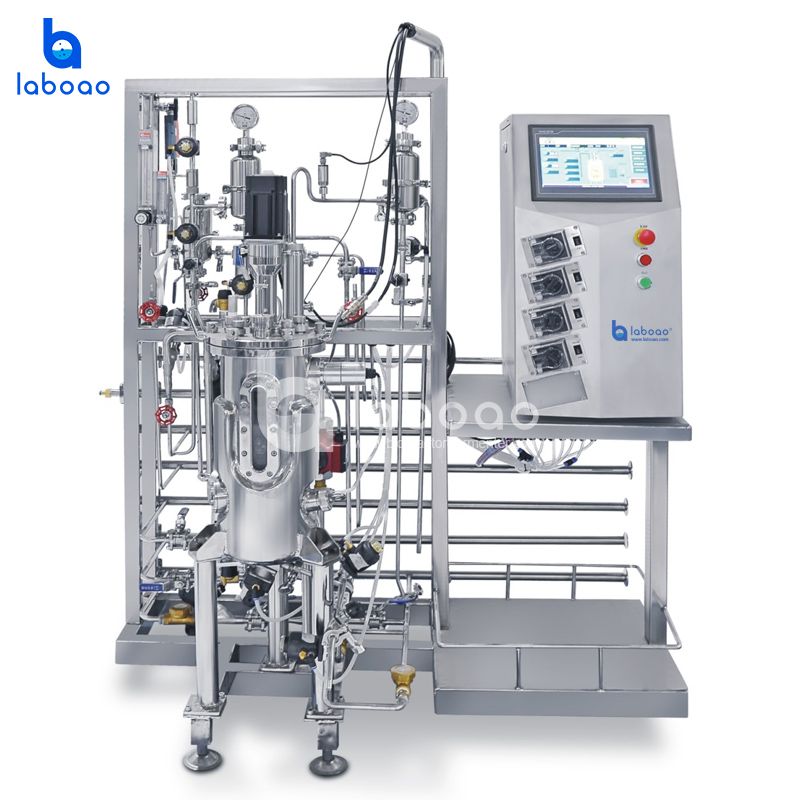

Stainless Steel Bioreactor Fermenter

-

Multiple Glass Bioreactor

-

Multiple Multistage Stainless Steel Fermenter

-

Cell Bioreactor Fermenters

-

Advanced Bioreactor Fermenter

-

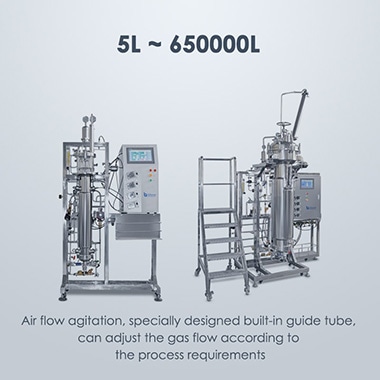

Airlift Bioreactor Fermenter

-

Solid State Fermenter

-

Pilot Production Bioreactor

-

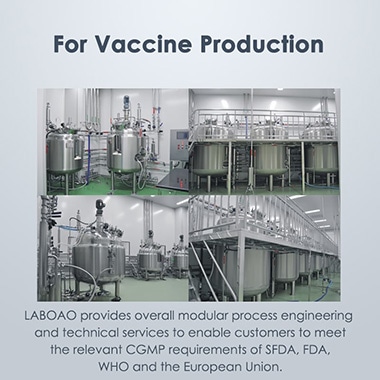

Biopharmaceutical Process Module

-

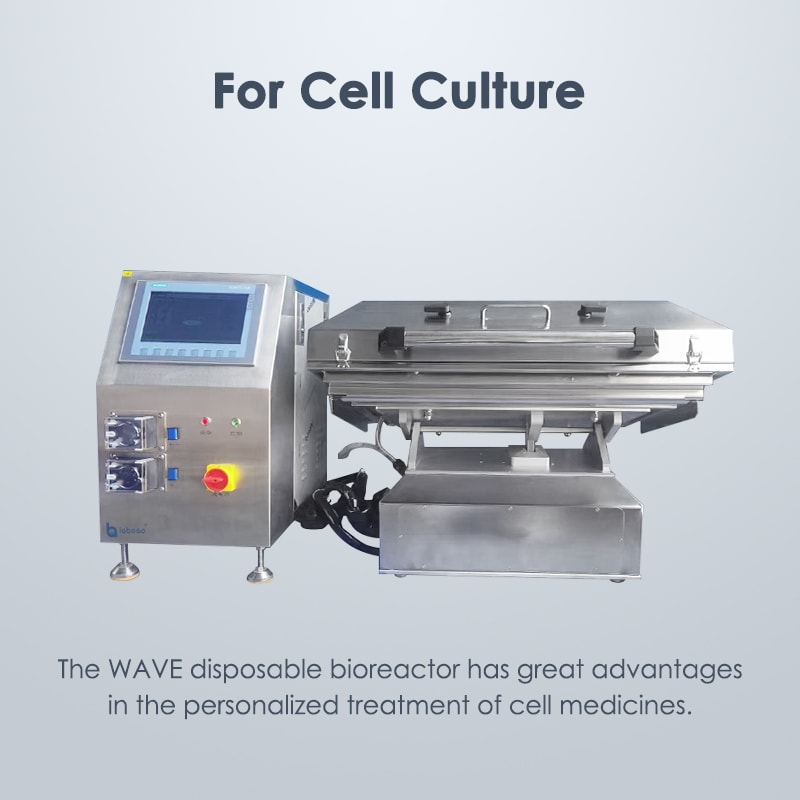

WAVE Bioreactor

FEATURES PRODUCTS

PROJECT CASE

LABOAO has a large number of experienced fermentation processes, and has provided bioreactor systems for more than 50 countries around the world, and has accumulated rich experience in bioreactor engineering such as design, production, installation, and commissioning. Our equipment parts use standard parts as much as possible, and the key parts are basically consistent with European products to ensure the quality of the products, and at the same time optimize the pipeline, facilitate maintenance and maintenance during operation, and reduce the use cost of customers.

ABOUT US

- Rigorous

- Easy

- Innovation

- Stability

LABOAO is a manufacturer and technical service provider specializing in complete solutions of bioreactors. Has 15 years of experience in fermentation process research and fermentation equipment manufacturing. LABOAO focuses on the biopharmaceutical and bioengineering industries, and its production services include: R&D, design, manufacturing and verification of high-standard sanitary containers and modular process equipment; installation and verification services in pharmaceutical factories/workshops; biological and pharmaceutical engineering design and consulting Service; Committed to becoming a leading provider of overall solutions for biopharmaceutical engineering in China. Our bioreactors are mainly used for Escherichia coli, yeast, fungi, insect cells, plant cells and animal cell culture, etc. The application fields include medical vaccines, animal vaccines, antibodies, microbial fermentation, cell tissue engineering, stem cell culture, recombinant protein drugs It can also be used as a production-scale fermenter for laboratory-level research and pilot trials such as , antibiotics, enzymes, and biofuels.

-

- 15YRS

Biological Fermentation

-

- 130PPL

Research & Design

-

- 20000SQM

Industrial Plant

-

- 7X24HRS

Technical Support

BIOREACTOR FERMENTER VIDEOS

LEARN ABOUT BIOREACTOR

-

Working Principle And Operation Process Of Fermentation Tank

Fermentation equipment plays a crucial role in modern industrial production and scientific research. Whether in the food and beverage industry (e.g., yogurt and beer production), or in animal health, environmental protection, plant protection, gut health, cosmetic raw materials, or biopharmaceutical industries (e.g., the production of various biological products), fermentation equipment is indispensable. A thorough understanding of the principles and usage of fermentation equipment is essential for ensuring production quality and improving efficiency. -

How To Choose A Suitable Bioreactor

In fields such as biopharmaceuticals, cell therapy, and enzyme catalysis, bioreactors are core equipment for achieving efficient biotransformation. The selection of a bioreactor requires consideration of "demand-performance-cost," aiming to meet current process requirements while also allowing for future technological upgrades. -

How Can Fermentation Tanks Be Maintained To Extend Their Service Life

Fermentation tanks are not static containers; they are not only the core vessels for industrial bioreactors but also crucial for ensuring production safety and product quality. Every valve turn, tank pressurization, and aseptic aeration tests the stability of this precision system. Neglecting routine maintenance, leading to minor wear and tear or the accumulation of impurities, will ultimately result in frequent downtime, contamination crises, and the scrapping of entire batches of products. Each repair attempt represents sunk capital for the company's production. A rigorous set of maintenance procedures is the core hub for ensuring its long-term, efficient, and safe operation.