The method of pretreatment depends entirely on the properties of the separable substance, such as stability to pH and heat, whether it is protein or non-protein, the mass and size of the molecule, etc. The specific methods mainly include the following:

1. Heating method

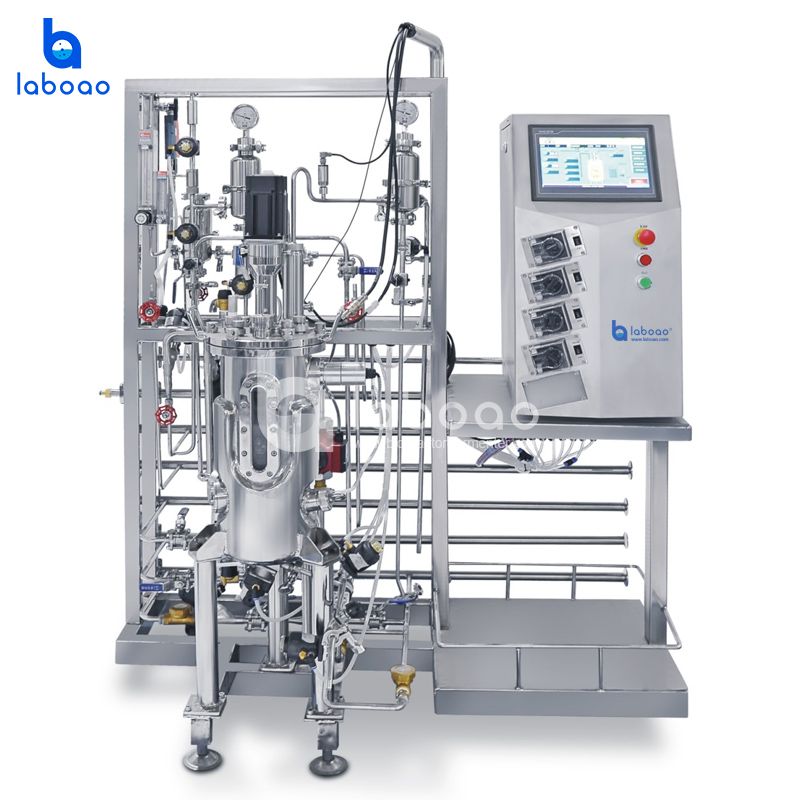

The heating method is the simplest and cheapest pretreatment method, that is, the suspension is heated to the required temperature in the fermentation tank and kept warm for an appropriate time. Heating can reduce the viscosity of the liquid. According to the principle of fluid mechanics, the rate at which the filtrate passes through the filter cake is inversely proportional to the viscosity of the liquid. It can be seen that reducing the viscosity of the liquid can effectively increase the filtration rate.

At the same time, under appropriate temperature and heating time, proteins can be aggregated to form aggregates of larger particles, which further improves the filtration characteristics of the fermentation broth. For example, after adjusting the acidity of streptomycin fermentation broth to pH 3.0 and then heating it to 70°C for half an hour, its viscosity will drop to 1/6 of its original value, and the filtration rate can increase by 10 to 100 times.

The heating temperature and time must be strictly controlled when using the heating method. First, the heating temperature must be controlled within a range that does not affect the activity of the target product; secondly, if the temperature is too high or the time is too long, cells will dissolve and intracellular substances will leak out, increasing the complexity of the fermentation broth and affecting the subsequent separation and separation of the product. purification. Therefore, the key to the heating method depends on the thermal stability of the fermenter.

2. Adjust the pH value of the suspension

Adjusting the pH value of the suspension is one of the most commonly used methods for pretreatment of fermentation broth in the fermentation industry. The pH value directly affects the ionization degree and charge properties of certain substances in the fermentation broth, so appropriately adjusting the pH value of the fermentation broth can improve its filtration characteristics. For amphoteric substances such as Aa and Pro, their solubility is minimum at the isoelectric point, which is the isoelectric precipitation method.

For example, in the production of MSG, glutamic acid is extracted using isoelectric point precipitation; in membrane filtration, macromolecular substances in the fermentation broth are easily adsorbed to the membrane, and the charge properties of easily adsorbed molecules can be changed by adjusting the pH value. Reduce clogging and pollution.

3. Coagulation and flocculation

Coagulation and flocculation are both important methods for suspension pretreatment. The treatment process is to add chemicals to the suspension in the fermentation tank in advance to change the dispersion state of colloidal particles such as cells, cell fragments, bacteria and Pro, destroy their stability, and cause them to condense into larger particles, which is convenient for Increase the filtration rate, effectively remove impurities and solid impurities, and improve the quality of the filtrate. However, coagulation and flocculation are two different methods, and their specific processing processes are still different. They should be clearly distinguished and cannot be confused.

Coagulation is to add some kind of electrolyte to the colloidal suspension, under the action of electrolyte heteroelectronic ions, the double layer potential of colloidal particles decreases, so that the colloid loses its stability and makes the particles coalesce with each other to form a lumpy cohesive body of about 1mm in size.

4. Adicione auxiliares de filtro

Filter aids are incompressible porous particles that can loosen the filter cake and increase the filtration rate. This is because after using filter aids, a large number of fine particles in the suspension are adsorbed to the surface of the filter aids, thereby changing the filter cake structure, reducing the compressibility of the filter cake and reducing the filtration resistance.

Commonly used filter aids include diatomite, cellulose, asbestos powder, perlite, clay, carbon particles and starch. The most commonly used one is diatomite, which has great adsorption and penetration capabilities, can filter out particles of 0.1 to 1.0 μm, and has stable chemical properties. It is not only an excellent filter medium, but also an excellent filter aid.

5. Add reactants

In some cases, by adding some reagents that do not affect the target product, the impact of certain impurities in the fermentation broth on filtration can be eliminated, thereby increasing the filtration rate.

The added reagent reacts with certain soluble salts to form insoluble precipitates, such as CaSO4, etc. The generated sediment can prevent the bacterial cells from adhering and give the hyphae a blocky structure. In addition, the sediment itself can be used as a filter aid and can coagulate colloids and suspended matter, thereby improving the filtration performance. If the reactants and reaction conditions can be correctly selected, the filtration rate can be increased by 3 to 10 times.

If the fermentation broth in the fermentor contains insoluble polysaccharide substances, it is best to use enzymes to convert them into simple sugars to increase the filtration rate.

For example, vancomycin uses starch as the culture medium. Add 0.025% amylase before filtration of the fermentation broth. After stirring for 30 minutes, add 2.5% diatomaceous earth as a filter aid, which can increase the filtration rate by 5 times.