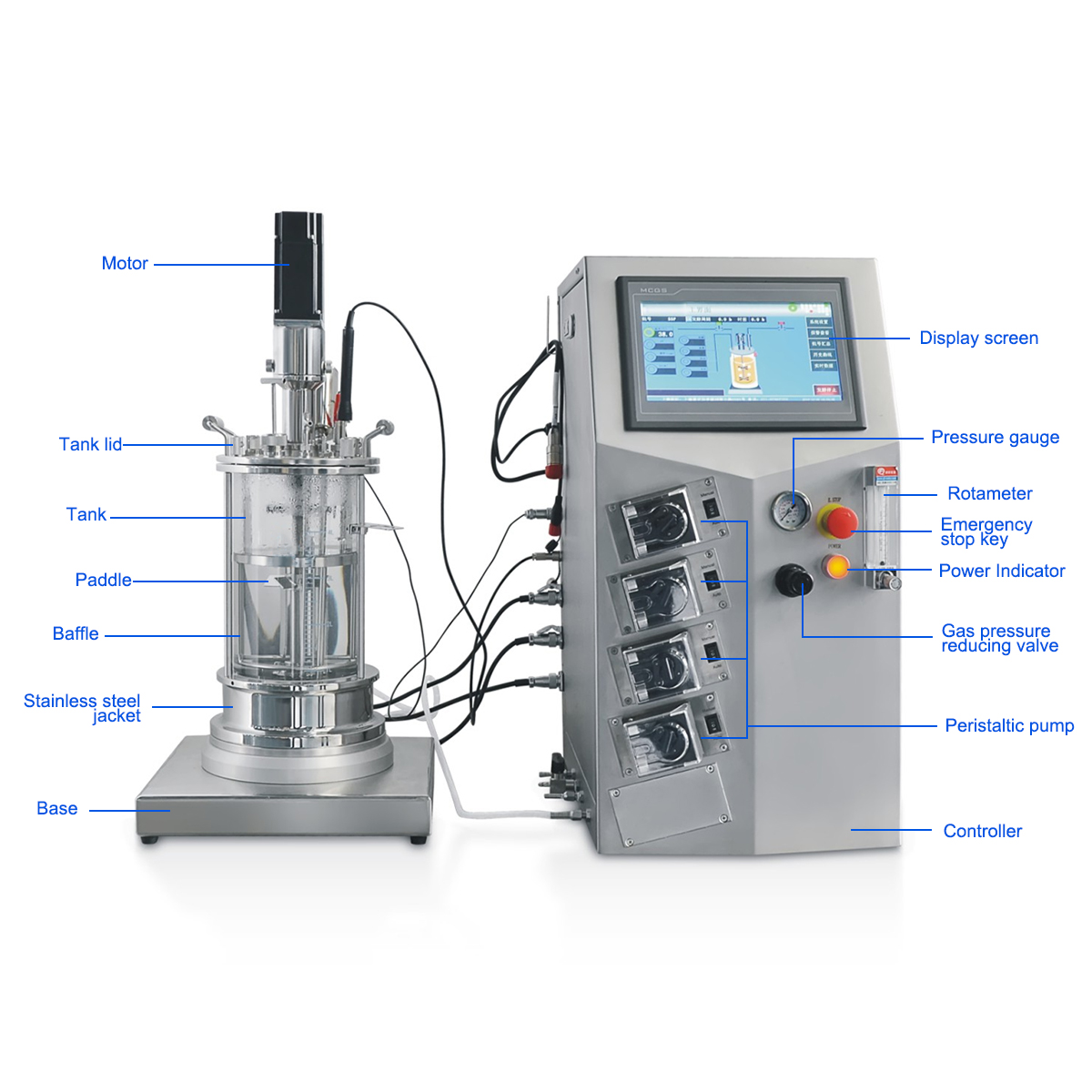

OVERVIEW

BLBIO-XGCA desktop in-situ automatic sterilization magnetic stirring is convenient for sterilization, good biological safety, small footprint, simple structure and stable operation

BLBIO-XGC series multifunctional glass biological fermentation system adopts color touch screen to display all measured values and control parameters, which greatly facilitates the user's operation. 4 peristaltic pumps are installed on the front of the control box, which can replenish the fermenter with acid, alkali, defoamer and medium. Various parameters in fermentation such as pH, DO, temperature and rotational speed can be monitored by the controller, and all data and control parameters can be transmitted to the controller or computer. The structure is compact, and various components can be integrated on the fermentation system. It adopts the direct coupling mechanical stirring method driven by the upper part or the indirect coupling mechanical stirring method of the lower driving magnetic force. The structure is simple and the operation is stable. The sterilization method is in-situ automatic program sterilization.

Nominal volume: 1/3/5/7/10/15 liters

Diameter to height ratio: 1:2~3; Liquid loading coefficient: 70%

Tank body: high temperature resistant, acid and alkali resistant, corrosion resistant borosilicate glass cylinder and 316L stainless steel combination,

Ventilation: Rotameter display, adjust the flow of gas according to process requirements

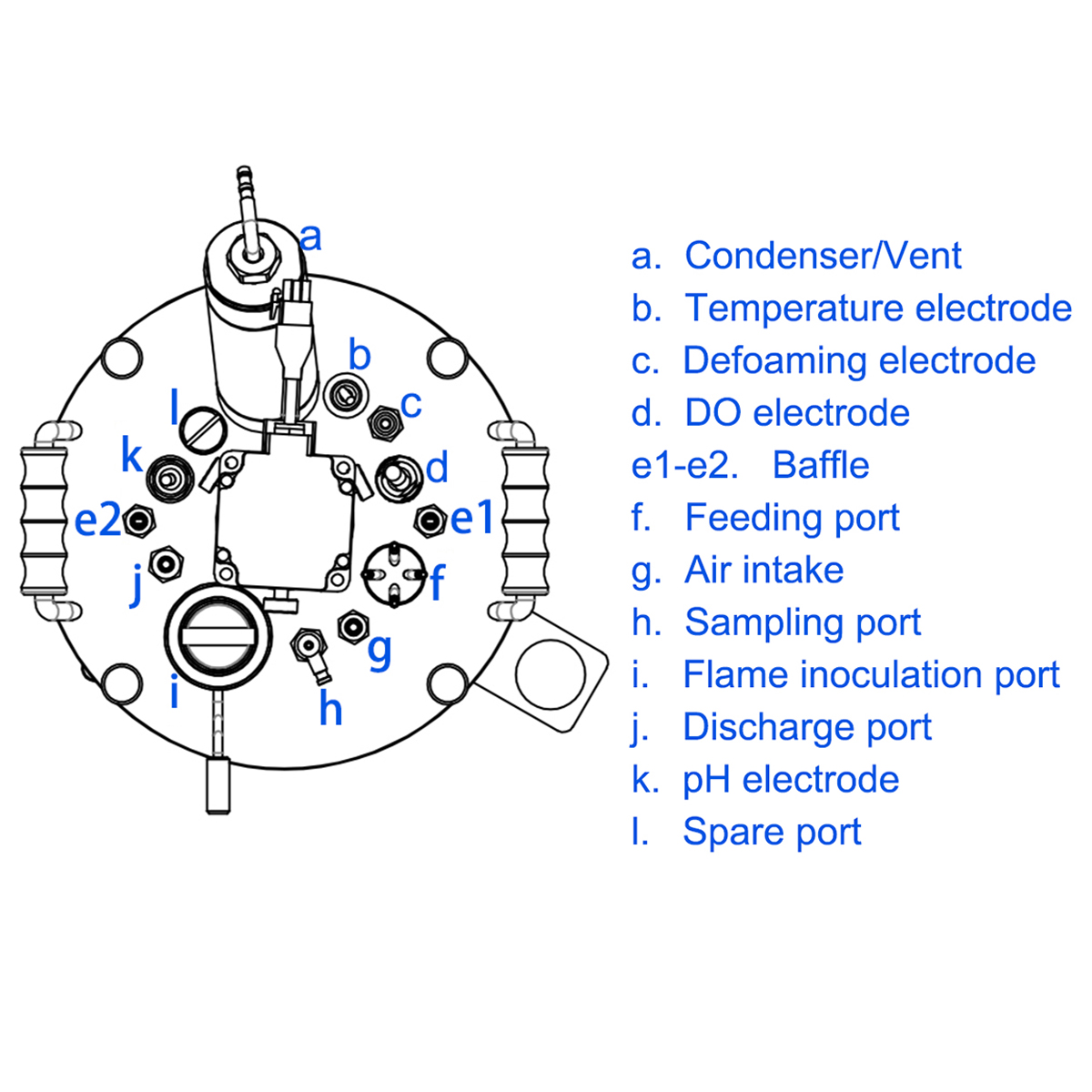

Fermentation pH control function: intelligent PID control, Mettler PH electrode;

Fermentation dissolved oxygen control function: intelligent PID control, METTLER DO electrode;

Temperature control: intelligent PID control, stainless steel jacket electric heating, water cooling

Feeding: a complete feeding system (acid, alkali, foaming enemy, culture agent), which can be fed regularly and quantitatively;

Sterilization: In-situ automatic program sterilization; Inoculation: Alcohol flame inoculation;