OVERVIEW

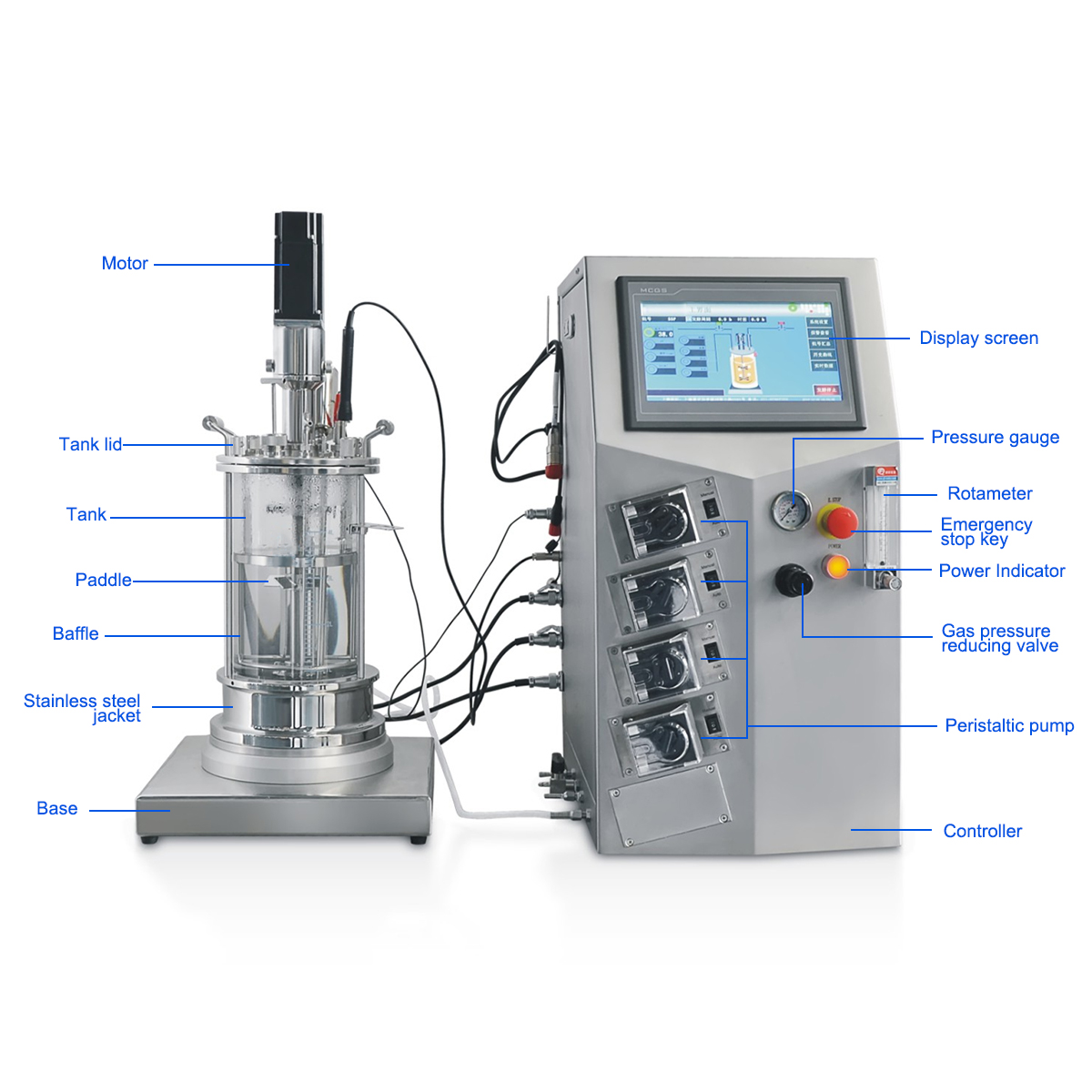

LBR-XGCA desktop in-situ automatic sterilization magnetic stirring is convenient for sterilization, good biological safety, small footprint, simple structure and stable operation.

Stirring system: The magnetic stirring system adopts a strong magnetic mechanical suspension magnetic stirring system (fully sealed, zero leakage, pollution-free, maintenance-free, and suspended magnetic stirring system. The dynamic seal is changed to a static seal, which completely solves the problem of biological product tank culture. The problem of bacterial contamination, there is no thimble at the bottom,) the speed is stable; the inner parts of the tank are all installed on the tank cover, which is very convenient for maintenance and cleaning; the design of the separation of the motor and the tank body greatly reduces the weight of the tank body, making the operation easier and more convenient, saving money Lots of manpower. The magnetic stirring system adopts special permanent magnet material, unique processing technology, and never fades magnetism. The highest stirring speed will not be lower than the technical requirements during the life of the fermenter. It can also reach the highest speed in high viscosity medium, and it can be fully automatic. The stepless speed regulation range of setting control is 50-1200rpm±5rpm.

Full volume: 1/3/5/7/10/15/10/15L, stainless steel tank + part of borosilicate glass

Diameter height ratio: 1:2~3; Liquid coefficient: 70%

Ventilation: Rotameter display, adjust the flow of gas according to process requirements

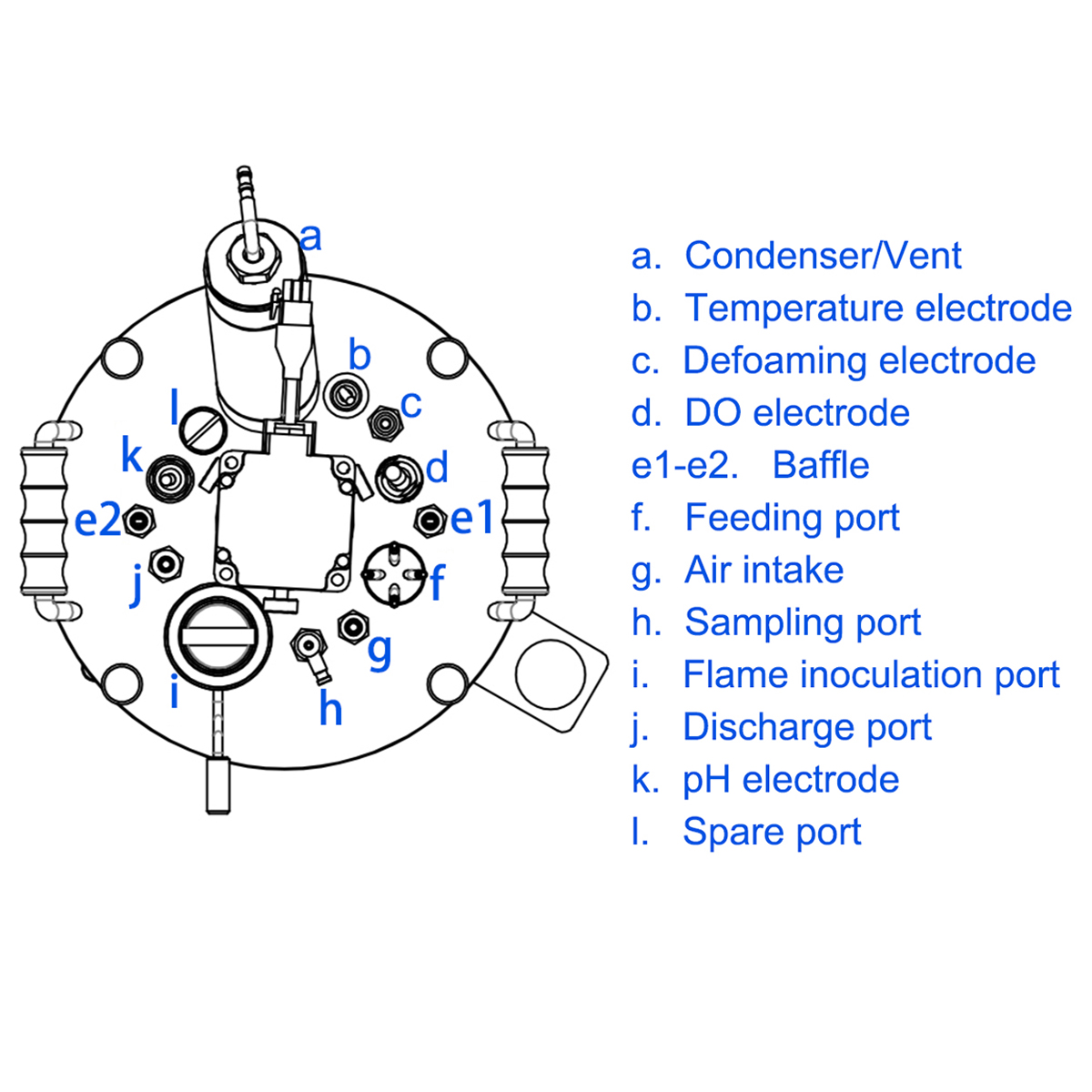

Fermentation pH control function: intelligent PID control, Mettler PH electrode;

Fermentation dissolved oxygen control function: intelligent PID control, METTLER DO electrode;

Temperature control: intelligent PID control, stainless steel jacket electric heating, water cooling

Feeding: a complete feeding system (acid, alkali, foaming enemy, culture agent), which can be fed regularly and quantitatively;